358 Mesh Hot Dip Galvanised Steel Security Fencing to Secure Perimeters

Anti Climb 358 Wire Mesh finds predominant use in fencing systems designed to bring maximum perimeter protection to a site. This style of mesh is universally accepted as the most secure form of high security welded mesh panel. 358 Mesh Fencing has significant inherent advantages over products such as chain link fencing or other forms of welded mesh fencing owing to its unique configuration. With razor wire coils above mesh panels, 358 mesh makes ideal port boundary perimeter fence.

358 high security mesh is supplied in a varieties of materials:

358 mesh panels hot dipped galvanised;

358 panels made from Galfan/ Bezinal (Zinc Alu) wire;

358 galvanized and powder coated perimeter security fencing panels.

Exported to:

Portugal, UK, Saudi Arab and other countries.

Anti Intruder & Anti Climbing Perimeter Fence Projects:

Project A, PVC Coated Perimeter Security Fencing panel Size 2.0m x 3.0m with a mesh size of 50mm x 200mm. Panel heights ranging from 7’ to 25’ high. Delivered to Portugal.

Project B,

358 Hot Dip Galvanised anti-climb security fencing materials to secure perimeters:

1. 2.8m in height of the ground with provisions for razor wire attachment.

2. 300mm stand of underground level.

3. 200mm wide with reinforcement mesh/bar.

4. All posts, attachments and fittings.

Project C, 358 Security Fence for 600mts perimeter, topped with razor wire. 3.1m high above ground, with a mesh aperture of 75mm x 25mm.

Material:

Low carbon steel wire, hot dip galvanized, or plastic coated.

Fence Height:

1.8m, 2m, 2.4m, 2.7m, 3.0m, 4.0m, 5.2m

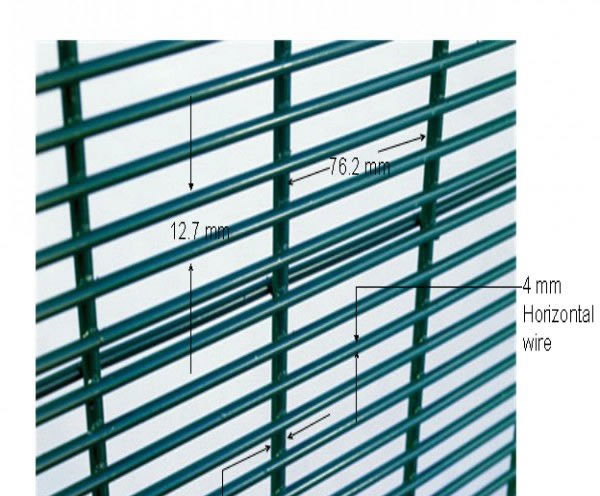

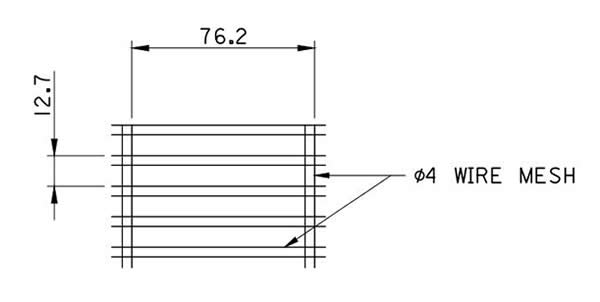

Mesh size:

76.2mm x 12.7mm

Horizontal Wires:

4mm --6mmx 12.7mm centers

Vertical Wires:

4mm -- 6mmx 76.2mm centers

Post Centers: 2.5mm

358 anti climb mesh is extremely difficult to penetrate, with the small mesh aperture being effectively finger proof, and extremely difficult to attack using conventional hand tools. '358' comes from its measurements 3" x 0.5" x 8 gauge which equates to approx 76.2mm x 12.7mm x 4mm in metric.

Panel height options: 1.8m, 2.1m, 2.4m, 3m

Panel width options: 2.2m, 2.4m, 3m

Hole size: 12.7x76.2mm;12.5x75mm

Wire thickness: 4.0mm

Post length: 2700mm, 3000mm, 3600mm

Post size:60x60mm, 60x80mm, 80x80mm

Material: Galvanized wire heavily galv.

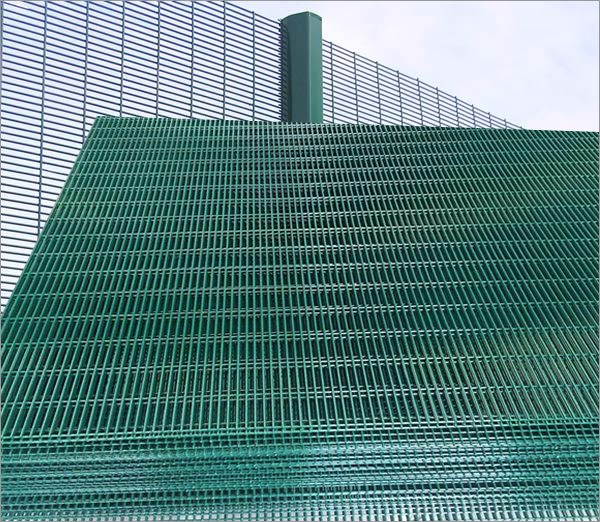

Port Perimeter Security Fence

The fence is supplied in according to International Ship and Port Facility Security (ISPS) code, to enhance the security of ships and port facilities for harbour areas.

The combined security systems to maintain the Port Security internally and externally including:

• Anti Climbing Port Perimeter Security Fence:

High security fencing shall be provided for the port boundary perimeter with a

stainless steel razor wire topping. This fence shall comprise unclimbable fence panels between

80mm x 60mm posts which will be concreted in position. The fence will be topped with

coiled razor wire.

• Internal Boundaries Security Fencing:

Internal security fencing shall be erected around specific areas of the port affected by the

Works.

• Security Gates and Anti- Intruder Detail:

Security gates shall be erected at the required locations. An ‘anti-intruder’ tops shall be installed on the top of the port perimeter fence.

• Security Lighting and other miscellaneous security items:

Security lighting shall be provided along the secure boundary.

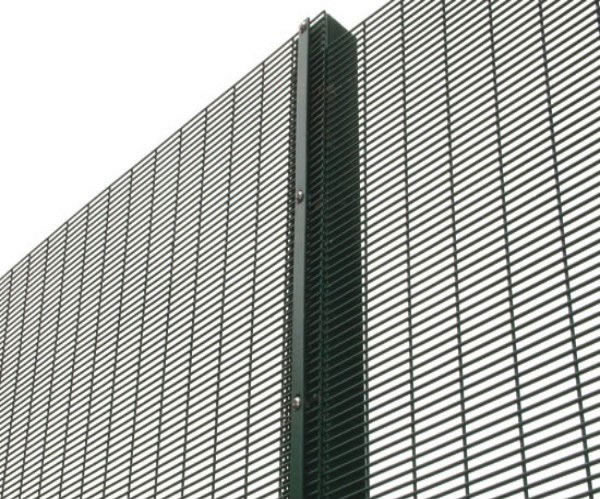

High Security External Fencing

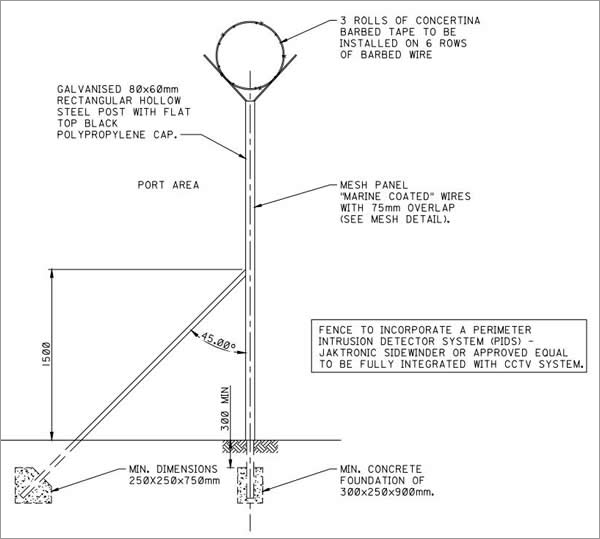

High security fencing panels such as Security mesh (358mesh) or similar shall be provided. The fencing has a marine coat (galvanised) finish of 4mm. The fence shall be 3m high with twin cranks for 3 wires of barbed or razor wire on top. Minimum foundations shall be 300mmx 250mmx 900mm.

358 Mesh Panel

Anti climb mesh fence panels, width of 2.515m, 76.2mm x 12.6mm x 4mm mesh.

The post shall be rectangular hollow steel section as per the specification with minimum size 80mm x 60mm. Both inside and outside of the section to be hot dip galvanised to BS EN 1461 and supplied with flat post caps in black polypropylene.

The Mesh panels to be overlapped by 75mm at posts and fixed on the Port side, all to maintain the integrity of the fence.

Each post shall have a support stay at a fence height of 1.5m extending downwards into the Port side at 45°. This stay to be incorporated into a concrete support block of not less than 250mm x 250mm x 750mm.

Razor Wire

Three coils of galvanised razor of wire shall be located at the top of the wall and the bottom of the fence mesh. The razor wire shall be attached by galvanised crimped rings, at not greater than 300mm centres.

Anti-Intruder System

A combined alarm and electric fence deterrent, designed to provide a physical barrier which delivers a non-lethal shock and simultaneously alerts security of an attempted intrusion, shall be fitted to the top of the fence panels. This system to be linked to the perimeter CCTV cameras and give an exact location of the trigger incident to the Security Control Room.

Gate Posts

Gate posts shall extend above the ground to match the height of the adjacent fence, and shall come complete with galvanised hinge pins and baseplates (These items shall be galvanised after assembly, but before arriving on site)

Any gap between a boundary wall post and a gate post shall be covered with a three-layer coil of galvanised razor wire.

Internal Boundary Fences

Internal Boundaries Fence

Internal fencing complies with the provisions of the Specifications and in particular BS 1722 Part 10: Specification for anti-intruder fences in welded mesh.

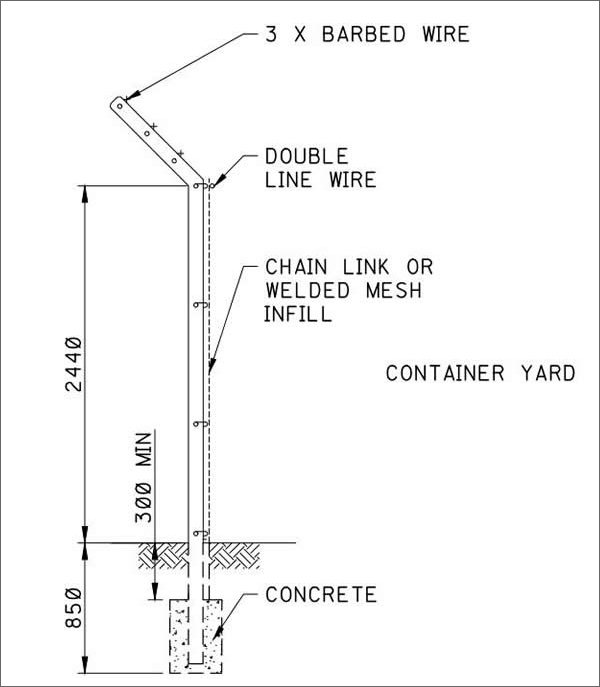

The internal fencing is Securimesh or similar. It is consisted by posts that are centred every 2.45m and has a height of 2.44m. The mesh centres shall be 76.2 by 12.4mm by 4mm thick. The foundations are constructed by concrete having minimum foundation sizes 300mm by 250mm by 900mm deep.

Posts are of circular hollow section suitable for heavy duty mesh as per Table 2 of BS 1722 Part 10 and the manufacturer’s recommendations. Posts galvanised with minimum dimensions 80mm x 60mm.

Intermediate straining wire restraints are installed at 1/3 points between the support posts securely concreted into the ground.

Temporary Fence in Chain Link or Weld Mesh

Temp chainlink fence extends from not more than 50mm above the top of the fence wall to a minimum height of 2.5m above ground level. Wire core diameter 3.5mm minimum diameter and wire size overall 4.75mm minimum diameter, mesh sides 50mm maximum.

The mild steel wire galvanised prior to the application of a bonded PVC coating. Mesh secured to top and bottom line wires with wire ties at maximum 150mm centres and to intermediate line wires at maximum 450mm centres, and then strained and secured at not less than 2.515 m centres by means of stretcher bars threaded vertically throughout the height of the mesh.

Galvanised ‘studding’ required for fixing the wire and not greater than 400 mm centres. The lower line wire is threaded through the mesh and a galvanised clamp plate. The plate is fixed to the fencing wall by nuts and washers located on the inside of the fence.

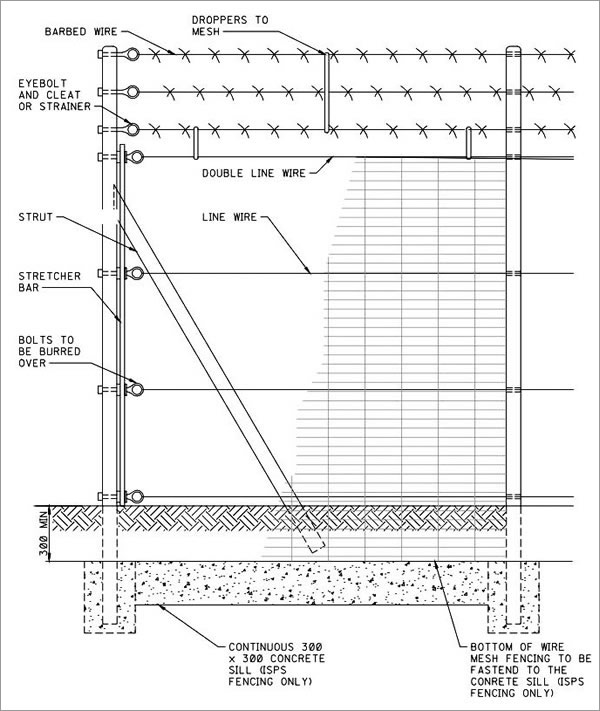

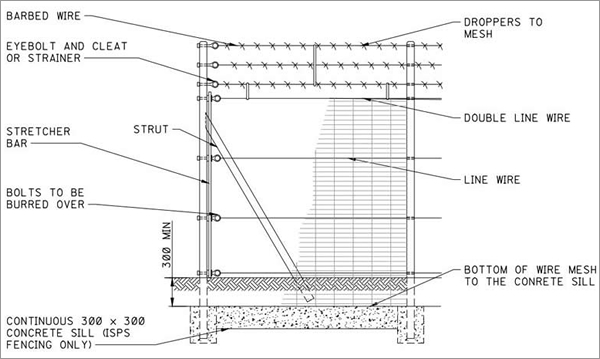

Line Wires to Mesh

The top “line wire” consists of two wires, one threaded through every other mesh, the other unthreaded. At least three other unthreaded line wires are provided below the top wires and equally spaced, the bottom wire being approximately 50mm above the bottom of the mesh.

All wires are galvanised mild steel sized in accordance with the fence manufacturer’s recommendations.

All line wires are attached to support posts by wire stirrups passing through holes in the posts, and strained at each straining point by means of winding brackets.

Straining carried out in accordance with the fence manufacturer’s recommendations.

Fence Gates

Internal Gates

Gate details for the internal boundariescomply with BS1722: Part 10, typically the gates are commensurate with the adjacent fencing, and are swing opening.

Gates are formed form circular hollow sections and shall be sized to suit the opening width. For openings over 2m width double leaf gates shall be used. Gate posts shall be from RSJ or UC sections as per Table 3 of BS 1722 Part 10.

A concrete gate sill of minimum size 250mm × 450mm deep is provided between gate posts, with the top surface at ground level and cast in sleeves for drop bolts. Adjacent surfacing is fully reinstated on either side of the sill.

Entrance Gates

Gate frames fabricated from rolled steel angle with mild steel panels, welded to the frame. Open panels are left clear of steel panelling. Mild steel bars 16 mm diameter minimum are welded across these open panels at not greater than 100 mm centres.

Each gate is topped with 3 lines of barbed wire and coiled razor wire fixed to extension arms on stiles and vertical braces. All steel shall be galvanised in accordance with BS EN ISO 1461. Where local limitations apply to galvanising, the gate may be galvanised in sections and assembled using galvanised bolts, nuts and washers, the bolt shanks being buried over after assembly to prevent loosening.

Single gates are used to fill openings up to 2m in width and double leaves of equal widths to fill openings up to 10m in width.

Gates are side hung vertically to give not greater than 50mm ground clearance at the meeting point. Double gates have 12mm maximum gap between meeting stiles. Sleeves for drop bolts shall be provided cast into a concrete sill.

The gates are provided with a vertical drop bolt on each leaf, a sliding bar lock with padlock eyes and a seven lever galvanised padlock with duplicate keys.

All hinges and other moving parts are greased before assembly and the whole gate securely supported whilst being assembled in position.

Gate House

A gatehouse is provided in the location given.

The floor level in the gatehouse shall be elevated such that the staff are at the same level as the truck drivers.

The building shall have an air conditioning system that maintained to a positive air pressure to prevent ingress of vehicles fumes into the gatehouse.

Windows to be fitted with security shutters.

Concrete Gate Sills

A concrete gate sill of minimum size 250 × 450 mm deep provided between gate posts, with the top surface at ground level and cast in sleeves for drop bolts. Adjacent surfacing is fully reinstated on either side of the sill.

Vehicle Gates

Vehicle gates are provided, as an automatic rising arm barrier with a bottom skirt. Operated manually and electrically.

Gates are constructed to match the height of the adjacent fence and manufactured from the same size steel tubes and mesh.

The bottom of the gates have a ground clearance of no more than 80mm. When closed, the space shall be not more than 25mm between the meeting stiles.

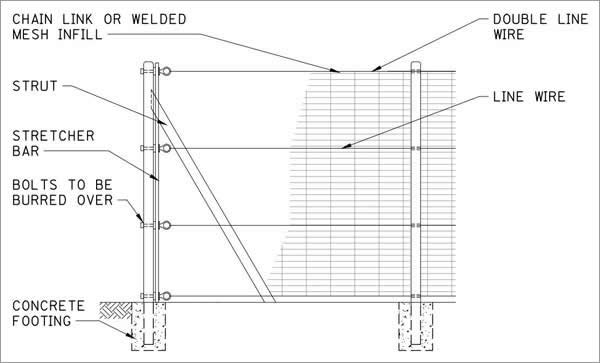

Typical International Ship and Port Facility Security (ISPS) Fence System Illustrations

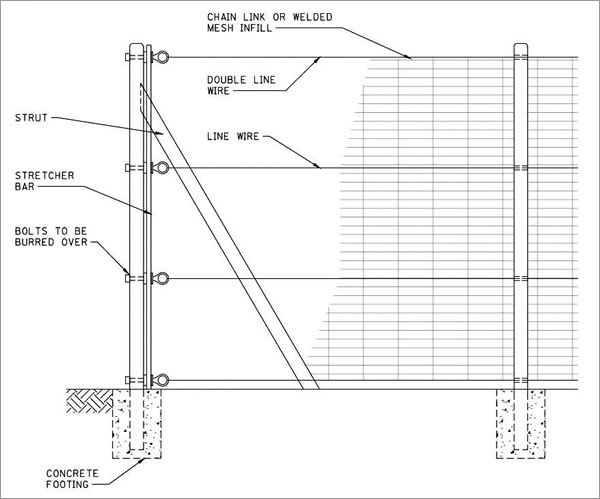

Typical isps fence detail: 358 weld mesh + barbed wire+stretcher bar+double line wire

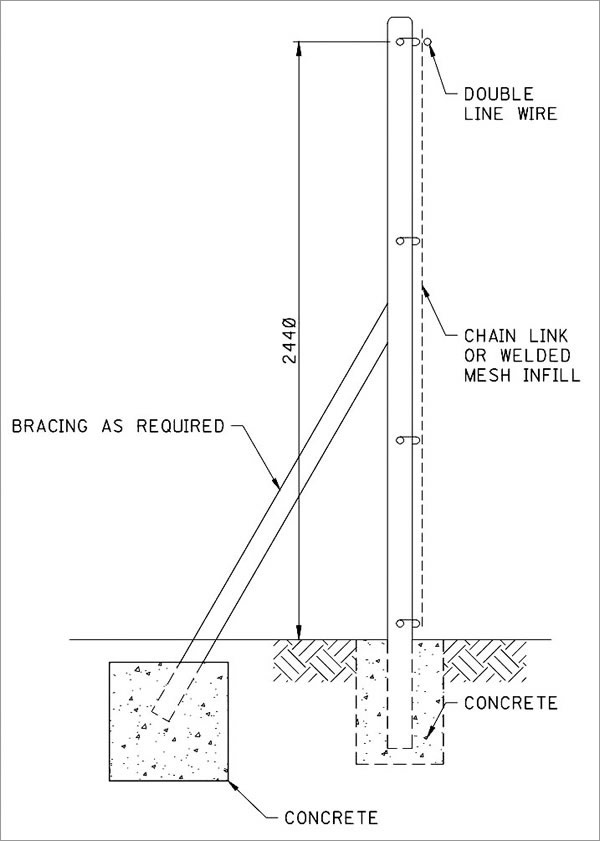

Internal port security fence detail section phase: Line wire + bracing +chain link or welded mesh infill

Internal port security fence detail elevation phase: 358 weld mesh + line wire + strut + stretcher bar + concrete footing

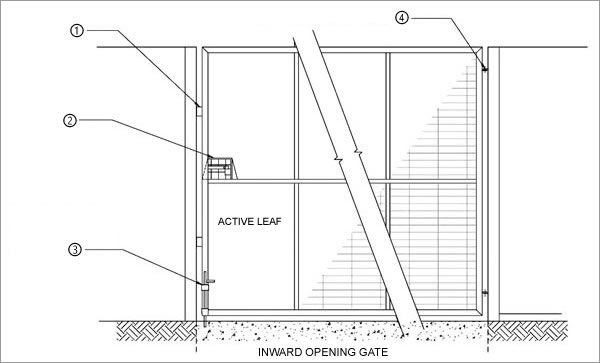

Typical single gate detail (Internal elevation) for port perimeter fence, with weld mesh infill

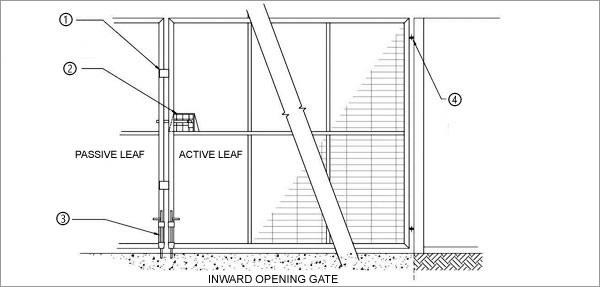

Typical double gate detail (Internal elevation) with 358 weld mesh infill

Note:

Stop plates welded to active leaf

Lock to be provided and prevent hand/foot holds

Drop bolts on both leaves into easy clean sockets (Accessed within site only)

Gates to be non-removeable and hinges to be tamper resistant.

Keep gaps between gate and ground, plus between leaves to a minimum.

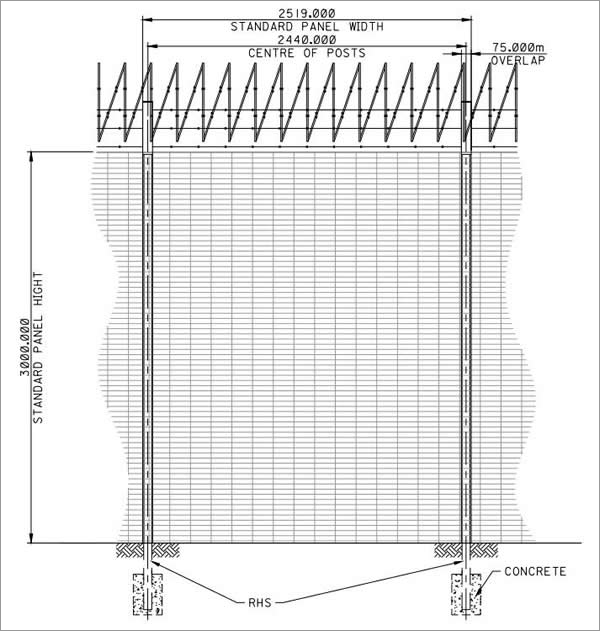

Port perimeter fence of secure welded mesh panel, standard panel height 3m, standard panel width 2519mm- Front elevation

Port perimeter fence - Side elevation- Fence to incorporate a perimeter intrusion detector system, fully integrated with CCTV system: Mesh panel of marine coated wires with 75mm overlap, galvanised 80x60mm rectangular hollow steel post with flat top black polypropylene cap, 3 rolls of concertina barbed tape to be installed above 6 rows of barbed wire.

Container yard fence - Front elevation- Galvanised,green coated pvc coated chain link mesh & line wire. Post surmounted with a single outward facing crank incorporating 3 strands of barbed wire. Bottom of wire mesh to be fastend to the conrete sill (For ISPS fencing only)

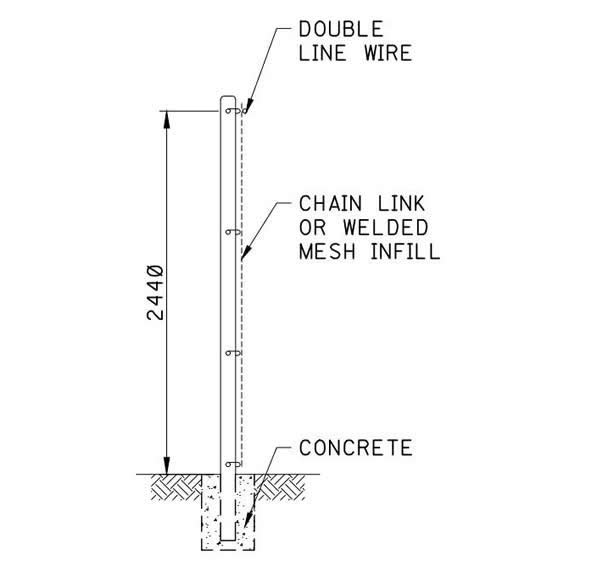

Container yard fence - Side elevation- 2.4m high panels, with double line wire, chain link or welded mesh infill, with 3 line barbed wire

Temporary fence, for Port Perimeter Fence System - Front elevation: Welde Mesh Panel, Strut, Strecher Bar, Line Wire

Temporary fence - Side elevation- 2.4m high galvanised,no requirement for barbed wire topping or pvc coating.

Wire Mesh Detail - Welded Mesh in 12.7x76.2 secure 358 style

Industry & Other Standards Applied for Construction of Port Perimeter Fencing System

1. The International Ship and Port Security Code (ISPS)

2. Safety of Life at Sea [SOLAS]

3. High Commission for Industrial Security [HCIS]

4. International Maritime Organisation [IMO]

5. BS 1722 – “Specification for Anti-Intruder Fences in Chain Link and Welded Mesh”

6. Illumination Engineering Society (IES).

7. International Labour Organisation (ILO) Code of Practice “Safety and Health in Ports”

8. International Commission on Illumination (CIE – Commission Internationale de L’Eclairage)

Technical Report 129 – Area Lighting for Work Areas.

9. BS 7958 – “Closed circuit television (CCTV). Management and operation”

10. BS8418 “Installation and remote monitoring of detector activated CCTV systems”

11. EN 50132 – “Alarm systems. CCTV surveillance systems for use in security applications.”

12. BS EN 50133 – “Alarm systems. Access control systems for use in security applications.

System requirements”

13. UK National Approval Council for Security Systems (NACOSS) code of practice

14. BS EN ISO 1461:2009 - Hot dip galvanized coatings on fabricated iron and steel articles.

Specifications and test methods

15. ISO 11064 – “Ergonomic design of control centres”

16. BS EN ISO 924 – “Ergonomic requirements for office work with visual display terminals

(VDT)s”

17. BS 5619 – “Code of practice for design of housing for the convenience of disabled people”

18. BS5810 – “Code of practice for access for the disabled to buildings”

19. BS 5940 – “Office furniture. Specification for design and dimensions of office workstations,

desks, tables and chairs”

20. BS EN 50133 – “Alarm systems. Access control systems for use in security applications.

System requirements”

21. UK National Approval Council for Security Systems (NACOSS) code of practice

22. EN60950 – “Safety of information technology equipment (IT Equipment)”

23. GB4943 – “Safety of Information Technology Equipment Including Electrical Business

Equipment“

24. UL60950 -“Practical Application Guide - Safety of Information Technology Equipment,

Including Electrical Business Equipment” Association of Public Safety Communications

Officials (APCO) P16 and P25 standards.

25. US Military Standards 810 C, 810 D and 810 E, for resistance to shocks and extreme weather

Other standards may also apply in supplying upon requests.

- Why is it called 358 mesh?

- Uses for 358 Mesh

- 358 Series Mesh Fence

- Anti-climb 358 Security Fence

- 358 Welded Mesh Steel Fencing

- 358 Electrical Substation Fencing

- Prison Mesh Security Fence

- Razor Type Barbed Wire Concertina

- 358 Mesh Perimeter Fencing

- 358 Secure Mesh & Trellis

- Anti-Cut Through Stainless Steel Mesh

- Heavy Weld Mesh 358 Panel

- Electric Wire Fence

- Other Secure Wire Mesh Fence

- Galvanized Wire Fence

- Picket Fence

- Palisade Fence

- Chain Link Fence